Ricochet is the best place on the internet to discuss the issues of the day, either through commenting on posts or writing your own for our active and dynamic community in a fully moderated environment. In addition, the Ricochet Audio Network offers over 50 original podcasts with new episodes released every day.

There’s a Great Future in Plastics. Think About it.

There’s a Great Future in Plastics. Think About it.

Years ago, when plastics were just starting to appear in our lives — I’m 64 — the thing we all hated about the trend was plastic’s serious structural drawbacks. How did we know about them? Because many common elements broke, especially when a plastic part was used to replace what was formerly a metal part. Remember how the internal car door and window handles used to break?

Slowly, over the years, things improved. Now we have really good plastics and really good applications for plastics. But there are still way too many unpardonable designs getting built by people who should know better. Do these manufacturers ever send people out to see how their products are used, holding up, or damaged? How are they holding up in their own shops? Aren’t they embarrassed?

These are three failures I’ve seen in the past couple of months. You can all add to this indictment, I’m sure. There are so many.

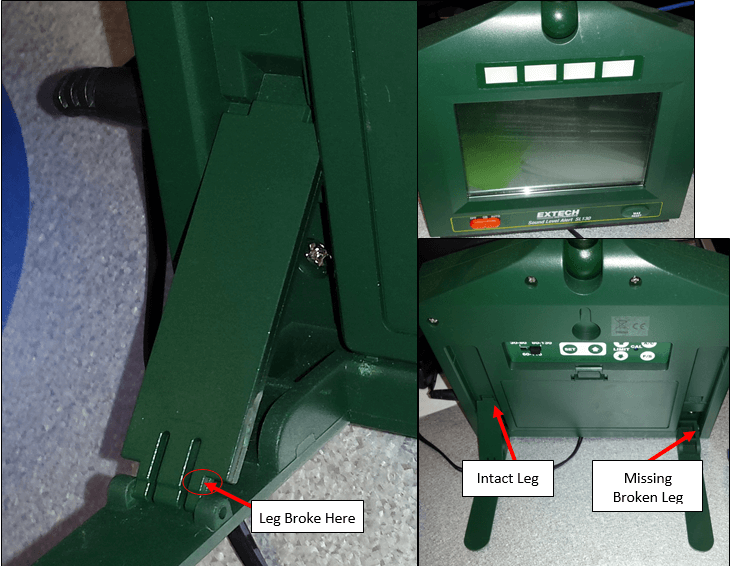

Example 1: Sound Meter. Think of the time that went into the mechanical design of the enclosure for this meter. Somebody did this. It is not difficult to see that the flimsy leg swivel point is too small. We have four of these. The first two both have broken legs, and one of them has both legs broken. We have two new ones. So far, so good. But how could the designer have failed to see by inspection that it’s a stupid design? These designers are morons. That’s the only explanation possible.

Example 2: VW Jetta (2013) cup holder. This is a part in the console between the front seats. In the picture below, you can see that the whole bottom has dropped by a couple of inches. When I rented this car, the holder was already broken. Doesn’t fill one with confidence, does it? Professional engineers were involved in the design and manufacture of this part. Morons.

Notice the little loop tab with the red arrow. I think there were six or eight of these, originally. Of course, the main problem is that they were too weak. But the compliance of the console’s upper support was such that it was probably easy, with a little force, to separate the bottom part from the upper part. Once one of these loops lets go (it needn’t be broken, just unsnapped) there’s an asymmetric load on the remaining ones. This is why they break. Morons.

Notice the little loop tab with the red arrow. I think there were six or eight of these, originally. Of course, the main problem is that they were too weak. But the compliance of the console’s upper support was such that it was probably easy, with a little force, to separate the bottom part from the upper part. Once one of these loops lets go (it needn’t be broken, just unsnapped) there’s an asymmetric load on the remaining ones. This is why they break. Morons.

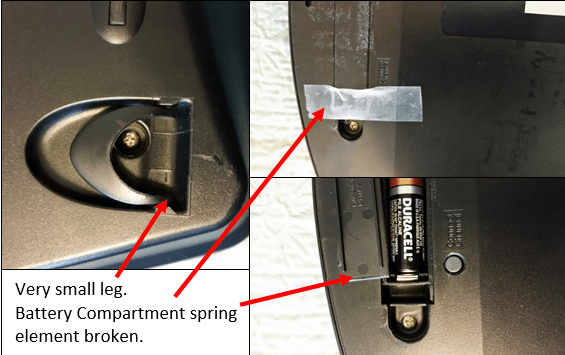

Example 3: Microsoft Keyboard. Cast your eyes around your own workplace: How many of the legs underneath your keyboards are broken? Don’t like that question? How often have you seen keyboards broken in the past 30-odd years? A lot, right?

My wife doesn’t use the legs of the keyboard below, so they’re intact, but notice the little battery door with the tape (of course). It gets used a few times in the life of a battery-operated keyboard because the batteries only last a few months:

Conclusion: Too many modern industrial designers are morons. Standard plastic is not strong enough to have small parts in designs that seem to be sized for steel or aluminum. If you look at the designs above, there are two issues: 1) pivots and swivels subjected to forces (foreseeable ones, dammit) beyond the yield and ultimate strength of the type of plastics commonly used in commercial products; and 2) the use of plastics as springs or springy elements.

Conclusion: Too many modern industrial designers are morons. Standard plastic is not strong enough to have small parts in designs that seem to be sized for steel or aluminum. If you look at the designs above, there are two issues: 1) pivots and swivels subjected to forces (foreseeable ones, dammit) beyond the yield and ultimate strength of the type of plastics commonly used in commercial products; and 2) the use of plastics as springs or springy elements.

As consumers, we should not have to put up with this shoddy kind of merchandise. The age of plastics is mature and well understood. Companies need to hire professionals for this kind of work. This isn’t a specialty area of design: All they have to do is apply standard techniques of material science, using the published values for plastics.

How can bad designs like these still be created in the modern age?

Published in Culture, General, Science & Technology

I do a bit of 3D printing at home. One of the interesting things about designing parts to print is figuring out how thick to make them. The printer I have (an entry-level hobbyist one) prints in PLA. It is a brittle plastic (but has very convenient thermal properties–it becomes workable at a pretty low temperature) so springy elements are out, but it’s entirely possible to make things that can bear a reasonable load. As you say, there’s no excuse for professionals, who have access to better plastics, to be making designs that won’t stand up under normal use.

Well, 3D printing is another thing altogether. We have a bit of a learning curve and difficult growing pains to go through yet in that field. And a lot of the things I’m complaining about here will be repeated again as new products are launched and new people get involved in this field.

Good luck with your printer. I’m excited about this technology. It’s amazing how many 3D parts I am seeing at Boeing in the R&D areas. They are everywhere — sometimes half of the new parts of the machinery (gadget sized stuff) are printed right there in the machine shop. This is truly a revolution.

I’m so old that I remember when planned obsolescence was a bad thing.

Or is this more what consumers are willing to put up with because its cheap? For example cell phones have terrible voice quality as opposed to old land lines. 4G quality is noticeably better, but those phones and networks aren’t everywhere.

You are scratching where I itch, Larry. Just last week the little plastic knob on my stove cracked. I thought to myself, didn’t these used to be metal?

Then the handles on my Bosch washer and dryer broke off. Cracked plastic. My whole plastic house is falling apart.

These are great examples of something close to malfeasance. What is it with manufacturers nowadays? Is it simply that they are morons? I really have a hard time believing that a stronger plastic part is too costly. My examples above are not costly to do correctly. I’m just amazed at how common this problem is.

Do you remember “pot-metal” tools from Japan and Korea when we were kids — that broke so easily? Those people really fixed that problem, didn’t they? I really admire both these countries for the responsiveness they have to their customers.

C’mon, Fellas. We’re Men. Men of the Right, even. We’re intelligent and resourceful. We don’t see problems and complain about ’em. We see opportunities, seek solutions, and do it Ourselves.

When Life gives Us lemons We… get the Duct Tape.

[an aside: I know for a fact that Big Plastic is in cahoots with Big Duct Tape]

Larry have you been under the hood of your car lately? Intake manifolds, radiator tanks, thermostat housings (I just had one for a Ford truck in my hand earlier this evening and right from the box it had a spun threaded insert) water pumps, impellers, etc etc etc.

I was looking at some upcoming BMW motors that were going to have a plastic engine block. Only the cylinder liners, cylinder head deck and the crank journals will be made of metallic alloys. The rest will be a high temperature thermo-plastic.

Not sure if I should be impressed or scared given what a BMW engine costs if it needs to be replaced before my expected 200K miles.

Time will tell.

I had a car in the eighties that had a lot of plastic. One night in Pittsburgh it got very cold. Something like -15. Every knob or dial that I touched broke. I think the car was a AMC Egale. When it warmed up I super glued everything back together.

Everything is made by the lowest bidder.

Good plastic part design can be and is done by people all over the world. BMW is a premiere company and their engineers know how to integrate plastic parts into their cars. I’m angry about how many poor uses and/or designs there are in common items in our lives that we all know are junk and we have to live with broken plastic items all over our lives these days.

Larry, I absolutely share your frustration with this kind of poor products. In fact my wife is an engineer who analyzes product failures for a living, from construction equipment to assembly line machinery to bicycles to smart phones. Some of her stories about failure investigations are really enlightening, entertaining, but also gruesome.

I can’t help wondering if some of these poor designs are the result of management or manufacturing engineers substituting cheaper plastics than the original design to cut cost. Cutting a few cents per part on a 100,000 part run can earn an employee a healthy bonus before any products end up in consumers’ grubby fingers to break them.

That’s not what I’m worried about. With good RFQs and specifications and contract administration, looking for the lowest bidder is good business sense. What blows my mind is that a company can hire people who take the time to draw up some of these designs, have molds built and then mass produce a piece of junk. What’s with the process here? Why is it plastics that are especially prone to this? Is it just as bad with other materials but plastics are more common? Still it blows my mind.

Some argue that it is due to the ‘day trader’ mentality of our investors that puts pressure on businesses for short term results. Maybe.

Edward Demming, the quality control expert who taught the Japanese quality control, said that 80% of quality problems are due to management. He said “Export anything to a friendly foreign nation but American management.”

Can someone who was there elaborate a bit about the good old days?

I’ve completely bought into the disposable culture. When something breaks I buy a replacement.

The argument I’ve heard in favor of this is Rolls Royce, the car (or air craft engine) without built-in obsolence.

People say Americans are too cheap to buy quality goods. They say you get what you pay for, but I’ve always found that you can pay for more than what you get.

This is one reason I love costco: they put guarantees on everything beyond the manufacturer guarantee, and I don’t have to get on the phone and fight for hours or weeks to try to convince someone I need a replacement. (At least, that’s the idea. I haven’t needed a replacement for anything I’ve purchased from costco except a hard drive that was a few years old.)

If I pay $3,000 for a washer/dryer combo (grabbed the number from costco search results for washing machine while logged in), should I expect it to NOT have built-in obsolescence, or is it a sign of the times and inescapable?

Even cheap metal is going to be expensive in terms of material, processing, weight … plastics win in all of the above. You are right though that the problem comes primarily in the design.

How much do these products cost to replace?

Keyboards? Dime-a-dozen. Heck, right now I’m typing on one I got for free from … somewhere. I don’t remember where.

If you can persuade yourself that you’re spending a half million on a car and it’s going to save you money, you’ve probably got a very strong urge to buy a Rolls. The insurance alone is likely to cost you enough to keep buying “disposable” affordable cars.

Once driverless cars are common, you’ll not find yourself driving the Rolls so much anyway (it won’t be too long before driving rather than working is understood to be a luxury/ hobby, and who has the time?) A Lexus purchased now should last you the rest of your life, and cost an order of magnitude less.

I bought an IBM Model M new-in-box for about $130 a couple of years ago. Manufactured in 1992.

It is analogous to the Clipper ship. If it is much cheaper, then it pays to buy and throw out a few years later.

One rule in aerospace engineering: if it does not break, then it is too heavy.

It’s not just plastics, Larry. The design problems also extend to metals. Why do they make the cans for jellied cranberry sauce (the large cans, not the small ones) with a recessed lid at one end? You can open one end with a standard can opener, but the can opener can’t get into the recess at the other end to open it. Have you ever tried to remove a cylinder of jellied cranberry sauce from a can with only one end of the can open? It’s nearly impossible to do without destroying the beautiful cylindrical shape of the cranberry sauce. It makes me so angry!

Stab a hole in it. When nobody’s looking, blow into the hole (this will not be easy) until the gelatinous mass begins to slide free. Recover outside with cranberry vodka.

Ask me how I know.

Planned obsolescence.

“One word. Are you listening? Plastics!”

I am a Mechanical Engineer and MBA, with over 20 years experience in Plastics. Before, I worked in Metals. I have worked in many areas. I have 14 patents world-wide in the field of plastic packaging.

Margins in most industries have dramatically fallen. Any product that does not innovate is subject to margin pressure. This causes pressure along the supply chain, and is a constraint for product lifecycle extension. Margins now reside in single digits for commodity products, and rarely over 10% in high-technology industries.

These problems create real opportunities for smart people to succeed. The people who find a way to design products that meet the needs of the marketplace and engender relationships end up being superstars.

Don’t complain about the product designers, complain about the market. The need for durable products has fallen as we have become a throwaway society. There are plastics available that will solve the problems the author presents. There are also design changes for each of the failures. Other manufacturers succeeded where these did not; this is market forces at work, and it’s a good thing.

And it should go without saying that there are manufacturers are all market segments. Not everyone has long-term durability as a key to their success. There are sales for high quality manufacturers, just as there are sales for low cost manufacturers. I’m sure you won’t be shocked to hear their functional results are different. Again, this is market forces at work.

I buy tools from DeWalt or Milwaukee when I want tools to last. When I just something obscure that needs to only keep working through one job, Harbor Freight.

Same customer, different market.

The troubles you’ve seen. They make me weep with terror.

The cranberry sauce cans are just the tip of the iceberg, believe me!

Yes, you have to break things during development to find the real limits but when manufacturing there is scrupulous effort put forth to stay inside those limits — with a safety margin. Otherwise, these modern marvels wouldn’t be one of the safest ways to travel.

I will quibble. Modern aerospace engineering is designed to contain failures, not eliminate them. So everything breaks, and when it does, (assuming it was designed correctly), nobody dies. I have been told that after a 737 or A320 has been in service for 10-15 years, there is not much on the airplane that is original off the factory floor. Everything breaks, and is replaced. NOTHING on an airplane is built to last indefinitely, and even though most parts are not “life limited”, everything gets inspected from time to time, and replaced when their state merits it.

This is why Maintenance, Repair and Overhaul (MRO) work is such a valuable piece of the industry.