Ricochet is the best place on the internet to discuss the issues of the day, either through commenting on posts or writing your own for our active and dynamic community in a fully moderated environment. In addition, the Ricochet Audio Network offers over 50 original podcasts with new episodes released every day.

I, Circuit Board

I, Circuit Board

Do you know how modern electronics are manufactured, or where they come from? Do you know where their component parts come from? The answers may surprise you. That cellular phone or computer you use to check Ricochet may say, “Made in China” on the backplate, but really it should just say, “Assembled in China, Made Everywhere Else.”

Do you know how modern electronics are manufactured, or where they come from? Do you know where their component parts come from? The answers may surprise you. That cellular phone or computer you use to check Ricochet may say, “Made in China” on the backplate, but really it should just say, “Assembled in China, Made Everywhere Else.”

There’s been much talk this election season about “getting tough on China” because of their manufacturing costs, or currency valuations, and there have been solutions proposed that sound like Great Patriotic Trade Wars to rectify the supposed ills of international trade, but unless you have some grasp of everything that goes into manufacturing, you are not likely even to begin to see the glimmer of the spiderweb of international trade that gets your computer into your hands.

No matter what electronic device you are using to read this (unless you printed it out), you are holding an assortment of components, chemicals, and raw materials that might have originated in over 40 nations around the world and passed through many others on their way to your hands. Some individual parts may have gone through three or four nations just during their own sub-assembly processes. You truly have a sample of the whole world in your hands or on your desk. I ought to know, as I am a part owner myself of an electronics manufacturer.

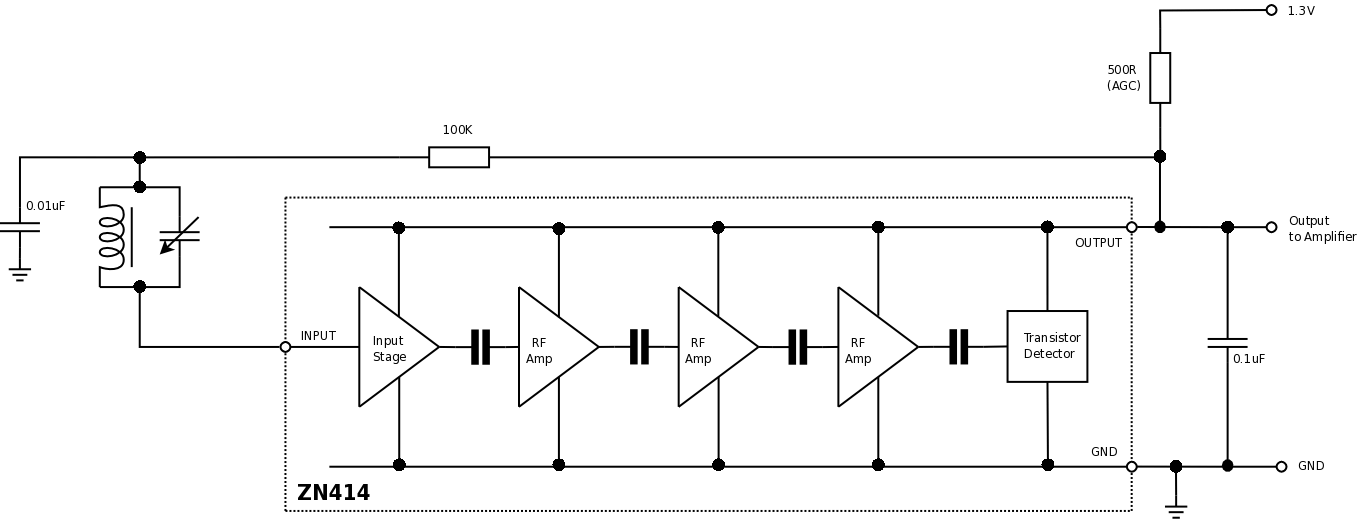

Before we begin looking at component origins, we should have a very basic review of circuitry. This is about as basic a circuit as you can envision:

We have an energy source with some voltage and a resistive load. Current flows from one pole of the source, through the resistive load (shedding energy as heat), and to the other pole of the source. You can make this circuit yourself with a battery, some wires, and a light bulb. Of course, you can make your circuit a lot more complicated too, depending what you want it to do:

Each element you see on this circuit is, in an electronics product, a discrete component,with its own part number and manufacturer, that you purchase and insert into what you’re building. What holds them all together? We don’t use discrete wires anymore due to cost and size requirements, but rather Printed Circuit Boards (PCBs), with the “wires” etched into copper layers embedded on fiberglass or films.

The basic circuit board starts its life as a sheet of fiberglass sandwiched between two layers of copper. Fiberglass is, of course, made everywhere. The copper could have come from recycled scrap or been mined from a wide variety of places around the world. A chemical process dissolves the copper where it is not wanted, leaving a maze of traces and pads behind. The process also leaves behind voids where components will be placed and pads to pick up the connection to the parts. Holes are often drilled through the board and plated through to pass signals to traces and parts on the opposite side, or to allow parts to be inserted through the board. PCBs are made the world over.

Looking now at the components themselves, the simplest component is the resistor. Resistors serve a very wide variety of uses, from simple energy dissipation to precision measurement of signals. They can be as basic as bent metal, but most are carbon films encased in plastic. Resistors are made by some suppliers you might know, such as Panasonic, but also by a wide variety of others, and are available throughout the world. Vishay, a supplier I use, manufactures many of its resistors in Israel. There are also original equipment manufacturer in the US, China, Japan, Korea, Germany, and Mexico. The resistors in your electronics might come from any of these places.

Moving up in sophistication we come to the capacitor. Capacitors serve as signal filters, energy banks, dampers, and other things. A capacitor is often represented as two metal plates, separated by distance, with a voltage applied across the plates. What fills the gap and prevents the electricity from flowing plate to plate is called the dielectric material. Some materials are ceramic, paper, or chemical, but here we also get into exotic materials like tantalum (which allows us to make very powerful but quite small capacitors). Tantalum is only mined in a few places in the world, and (according to Wikipedia) Rwanda was the largest source in 2015. The tantalum in your devices could have been mined in Rwanda, smelted elsewhere, then manufactured into capacitors in China, the US, Mexico, Japan, Malaysia, Europe, and elsewhere.

Now we move on to the semi-conductor devices themselves – the diodes, transistors, MOSFETs, regulators, processors, logic gates, and other forms of integrated circuitry. These begin life as a very pure extrusion of silicon, which is then cut into thin slices called wafers. The wafers are doped with sundry elements and have copper traces laid down an etched patterns through lithography processes. A variety of other processes produce the device cores. These very small cores are called dies. A wafer of a certain diameter can be turned into a gridwork of thousands of dies, depending on the part. These dies are extremely delicate, and can be extremely small. The processor core of your computer may have a die only a few square millimeters in size. What makes the parts you see appear larger is that this die is then bonded to wire leads on a frame (called a lead frame, which itself may well have been made somewhere else entirely), or sometimes to heat sinks, then encased in epoxy. Sometimes the dies are bonded to other parts first, and this can be a multistep process.

Just to take as an example a couple of components I use, two power MOSFET devices start life as dies in Europe (Austria and Italy). The completed dies are then sent to multiple plants, depending on the size and shape (the part’s footprint) required by customers. Some go to Morocco, others to Malaysia, others to Taiwan for the die bonding and packaging, then they wend their way back to Europe for quality control, and finally on to the US. One processor I use has its dies made here in the US, but is then sent to Japan for die bonding, whence it is shipped worldwide. The parts are often deemed as originated in the place of final manufacture, but in reality, they have passed through multiple nations. “Made in China” is hardly an accurate depiction of their origin.

This does not touch the other non-electric components of the products I manufacture. The hardware and product enclosures are made right here in Ohio. The silicones I use to insulate and protect the insides are made here, too. The stainless steel lug posts are also forged right here in Ohio. The solder used to connect the parts to the circuit boards is made in the US, and everything is finally assembled at my factory in Ohio. My products say “Made in the USA,” but really, they are made the world over.

This is why some sort of “trade war,” or “getting tough” with foreign competition, won’t save American jobs. Everything you touch, from your car to your computer, from your desk to your shoes, originated in multiple locations throughout the world. The cotton shirt you’re wearing? The cotton may well have been grown in Texas, turned into thread in North Carolina, but actually woven into fabric in Bangladesh. It’s tag may say “Bangladesh,” but can you say in truth that it came entirely from there?

There are reasons why raw materials and semi-finished goods are shipped halfway around the world for additional manufacturing. Sometimes it’s to reduce labor costs, sometimes it’s to utilize local expertise or resources, and sometimes it’s done because that’s where the customers are. The chains of origin are extraordinarily complicated for even simple items like T-shirts, and complex goods’ supply chains engulf our entire planet. Erecting tariffs and trade barriers indiscriminately, just to satisfy political whims, will not suddenly bring all of these processes back home. But it may well spark a trade war for which we will all ultimately pay. The manufacturing world is far more sophisticated and interdependent than you may realize, and country of origin is only a stamp that indicates the most recent place on the assembly line before your goods were shipped to you.

For fun, here is a video of a Samsung SM421i assembling a board. I have one of these in my shop, though this is a video of someone else’s.

This is considered a “slow” machine, for low volume or high-flexibility work, capable of up to 4000 parts per hour.

Here is a turret placer. These can do 80,000 parts an hour (I soooo want one!).

and another

Published in Economics, Foreign Policy, General

Egad, I can well imagine the complexity of that task. This is why I sell strictly B2B (business to business), so I don’t have to deal with the monstrosities of sales taxes.

This is also why I think a VAT, even as a replacement for the income tax, is a VERY VERY VERY EXTREMELY BAD IDEA. VAT sounds good on paper, but it is an accounting nightmare and prone to absurd levels of fraud.

As in cracking your brother’s sanity?

That sounds way worse than Mike Rowe’s “Dirty Jobs”.

Excellent article, skipsul. Thank you for writing it.

Less fun to watch, though.

My brother gained a wealth of cultural knowledge from it – his insights in how Indians think, for example, have been priceless. And they are based on their tax code.

My brother is a guy who can read thousands of pages of federal regulations and reduces them to a single page. OK, the text is kind of small, but it is a single page nonetheless.

Watching him manipulate an excel spreadsheet in a meeting has, in the past, caused the assembled engineers and bureaucrats to gasp, giggle, and even applaud.

My skill set is more limited: I recognize mad skills like these, and convince their wielders to work for our company.

Loved the videos of the robot assemblers. If a young lad wanted to pursue this type of work would electronic packaging be the engineering discipline?

I could not do my job without Excel. I have built some amazing things with it. My father in law, a printing estimator, runs circles around the young bucks in the business because he can build a 100,000 cell single sheet with every permutation of printing options.

Depends on what he wants to do. Skilled machine operators are rare (people who can program and run the lines), and can be decently compensated. But if he wants to design the products, then a full on Electrical Engineering degree is the way to go.

How It’s Made

Skipsul Style

Thanks!

Something is wrong here, but I just can’t put my finger on it . . . .

Depends on what type of work you want to do. If you want to fix robots, or do some basic programming on them, a 2 year degree in something like Electronics Technology works. If you want to do more involved programming, you might need a 4 year degree in something like Electrical Engineering Technology.

I will say, if you learn how robots work, the demand is high.

Awesome post.

But since nobody has done so yet, I’ll play the devil’s advocate: what would likely happen if we erected tariffs to prevent such subcomponent manufacturing from so easily crossing borders?

In other words, what are the driving factors for the geographical distribution of the numerous steps described in this post (aside from those associated with mineral extraction)? Is it primarily regulatory/tax issues, as mentioned by iWe with the VAT example? Is it cost of labor? Expertise of workers? Work ethic? Proximity to other niches?

In other words, in a hypothetical future with tariffs but less regulation in the US, could these supply chains be resurrected onshore with ease? With difficulty, but possible? With ease but at much higher cost? And why?

Help an ignorant biologist out. What are, in fact, the egregious errors here?

See where she is holding the soldering iron? See right where her fingers are that the iron is blackened from the searing heat?

Oh. My.

Is indiscriminate erection of barriers the proposal? I’m sure there’s some support for that even on the right, but my impression of what’s on offer is fairer and still free trade. Currency manipulation, intellectual property infractions, trade deficit, partners’ trade barriers to our goods. I think the threat of tariff and trade war isn’t for it’s own sake or for bluster, but they’re things to endure temporarily in order to make progress on real issues we face with our trading partners and eventually increase prosperity.

That’s only one side of the coin, and I’m not convinced that the only trade war possible is one that is equivalent to total nuclear war. Of course conservatism has much to offer on the domestic side of the coin to help improve the conditions for more productive economic activity to occur right here.

Otherwise thank you for the look into your business: that kind of thing is fascinating. One target of my fascination is that it’s apparently not too costly or inefficient to build so much shipping into the process. Seems like concentration of functions should be both more efficient and inexpensive.

Yep. Great post skip!

See the solder she isn’t holding in her left hand, so that all the right hand can do is melt the existing components on the board?

Part of what makes the shipping work in these cases is that many of the parts are tiny and lightweight. In some cases, you can ship thousands of them in one box.

Love How It’s Made! Love the post as well. Milton Friedman would nod approvingly.

Quite. On the resistors, if anyone here remembers 35mm film containers – you can fit 15,000 of the 0805 sized little buggers in one canister. If you go down to the 01005 size, you can fit upwards of 100k.

Well, to really nitpick (aside from that she’s self inflicting 3rd degree burns on her hand):

Also, her shirt is too clean. No one would wear a nice pressed shirt like that for soldering – too much risk of burn holes.

If this were the 90s, to be really accurate she’d also have a cigarette hanging out of her mouth.

My all time favorite for this sort of thing was for a school offering careers in the exciting world of computers. Shows a woman sitting in front of a desktop computer, holding the mouse in her hand, pointing it at the screen. Ad for a school…

BTW, this thread can’t be complete without this video…

My first job out of college was at a manufacturing plant. On one hand my desk was directly next to the door of the single occupancy restroom everyone in the office used. On the other hand, I was allowed to smoke at my desk (and I did back then, partially out of self defense from the office restroom).