Ricochet is the best place on the internet to discuss the issues of the day, either through commenting on posts or writing your own for our active and dynamic community in a fully moderated environment. In addition, the Ricochet Audio Network offers over 50 original podcasts with new episodes released every day.

Garage Workspaces – Starting Over

Garage Workspaces – Starting Over

For those of us who have a garage, it may simply be the place we park our car or store our stuff. For others, maybe the garage serves as an extra room or a studio of sorts. But in the end, for many people, it is just another space that they pass through. Not for me.

For those of us who have a garage, it may simply be the place we park our car or store our stuff. For others, maybe the garage serves as an extra room or a studio of sorts. But in the end, for many people, it is just another space that they pass through. Not for me.

Growing up, we moved around frequently. Sometimes we had a garage, sometimes we did not. When we did, it was far more than just a place to store things, more than a space to park the car; it was a refuge, a sanctuary from the outside world. It was a place altogether masculine: the smell of wood and cigarette smoke, the sounds of power tools, projects on the bench in various stages of completion, tools hanging on the pegboard or in hidden in their drawers but always in their proper place. It was a place to experiment, to build, and to swear. It was a place to try new things, fail, and try again. Perhaps I am romanticizing, but I don’t care. I want that garage. I want that workspace.

In the first house I bought, I built a simple bench and pegboard at the back of the garage. It wasn’t much, but it was suitable for limited storage and provided space for me to indulge in efforts to repair old console radios and turntables. My tool collection was limited in those early years, but I had all the basics. I had bigger plans for the second house, and so had a bigger workspace, but — due to the imposition of other priorities — it never lived up to its potential beyond the multitude of pinewood derby cars designed and built there. And then the tornado hit, and it was all gone.

I am moderately chagrined by the fact it has taken me more than two years in the rebuilt house to finally get around to setting up my work area. But the stars finally appear to be aligning, and I am now in the stages of planning my new workspace. To say that I am excited and a little giddy is an understatement. Not only am I anxious to build this space, I need to build this space. Perhaps some of you will understand that without me having to explain why.

The best part is, I get to start from scratch. This means the slate is clean, and I have the opportunity do it right from the start. I’ve scoured the Internet for ideas. I have a Pinterest board full of links to pictures, plans, and tricks and tips. (Hey, don’t laugh. Pinterest has links to tons of garage workshop ideas, tools, and other “manly” things). But I want more. While I pretty much know what I want do to, I’m still open to additional ideas.

Here’s where you come in, Ricochet. Do you have a garage workspace, or a workshop? What do you like about it? What would you do differently if you could? What configurations work for you? What don’t? If you have pictures you are willing to share, that would be great. It doesn’t matter to me if you’re a car guy or a woodworker, tell me about what you have, or what you wish you had.

Share and compare. One-upmanship is encouraged on this post, as a little envy can motivate one to new things. Tim Taylor grunting is allowed.

Published in General

I couldn’t agree more.

I installed 8 similar fixtures in my 20×40 garage a little over a year ago. They light the whole space nicely.

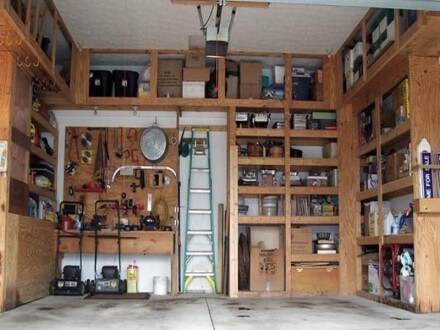

I’m not sure anything fancy is required to make a nice workspace. Organization is important. I’m a fan lots of pegboard, shelving, and storage bins. Keep frequently used tools easily accessible. Lesser user tools can be stored in cheap bins on shelves organized into categories to make them easy to find. If everything has a home, it’s easy to find. It’s also easy to put away, which makes clean-up faster.

My garage workspace is nothing fancy, but it works well.

What you don’t see in the photo is that nearly every wall is lined with inexpensive adjustable shelving.

Regarding your high ceilings, take advantage of all the space you’ve got. I keep a 4′ aluminum step ladder in the garage. It’s cheap, light, and plenty tall to reach stuff stored on 8′-9′ high shelves. I store stuff that I only use once or twice a year up high.

I’m not a big fan of drawers for frequently used tools. When I was less experienced and did keep my wrenches in the drawer of a rolling tool chest I did something like this:

The little plastic organizers you need for this are really cheap.

BTW, I gave away the tool chest. With my wrenches, sockets, and screwdrivers out where I can get to them in seconds, there was too little stuff left that would fit in those little drawers to justify the space consumed by the chest.

Finally, I’d advise against biners in drawers. Seems like to worst of both worlds to me. If you want to be able to remove an entire set of wrenches from a drawer at one time to take them with you, that may be a good option, but it can be pretty inconvenient getting a wrench from the middle of the set off of the biner. I keep the wrenches in my portable tool bags on biners though. Love them for that.

Tools with cords? You’re not making any sense.

I used pegboards in my earlier shops but went a different direction on the new shop. I mounted a sheet of 1/2″ wafer board with 2×2 board standoffs over the workbench. I use drywall screws instead of pegs to hang tools etc, they are cheaper and more flexible as to location. I h old the tool in place and mark with a felt tip marker then use a drill to put in screw(s). Having the space behind the board let me run wiring down for outlets along the shelf mounted under the sheet of wafer board. I sited the shelf and board above the bench by lying a 1×4 on the bench and putting several plastic coffee cans on that, resting the shelf/board on the cans then marking the concrete wall for mounting holes so I can use about 10 cans for small parts storage. I cut a slot in the lids and can then return extra screws nuts and so on without having to move the can or remove the lid.

It starts before the floor is poured. PEX tubing in the concrete for heat. Figure out ahead of time where your lift will sit, so the bolts dont go through your tubing. It is so nice to have warm floors when crawling under a car. Epoxy the floor too. Put in lots of outlets. Hang drywall and finish it with semi-gloss paint that is easy to clean. Install really good lights. Run air lines around the perimeter. Hang your speakers (you did rough in speaker wires, right?). Those are the basic requirements. Now move in whatever suits your requirements.

Big sheets of cardboard (corrugated paper to you purists) for sliding under vehicles. It’s good insulation, and works better than a creeper.

And now we’re talking about garage cardboard on this thread.

That’s a great idea!

You knew we’d get there eventually.

Thanks for the picture. I’m all about “everything in its place” too. I hadn’t really thought about adjustable shelves, at least for smaller items and bins. I had been geared more toward the big, heavier duty solutions. I need to chew on this some more. Thanks!

Alas, a bit too late for some of this. But I have tons of receptacles, I’ve brought CAT-5E and co-ax out for internet and TV. No speakers for now, but adding those wouldn’t be a problem. We also have a SONOS system that I could easily extend to the garage as needed.

How well I remember the wrath of my father should a tool not be returned to its proper place!

I had some friends a long time ago who kept a selection of “inside tools” inside their laundry/utility room. They managed to fit a small table in there, and, while not really a proper pegboard, they had a solution that served the purpose of one. It wasn’t unlike what OkieSailor described above.

That’s another project to put on the drawing board, after the garage. An inside tool station, somewhere. Hmm.

I’ve heard that too. I may not win, but I’ll aim to die happy!

That’s a table. The bench I lost a few years ago had a steel frame, but a massively heavy 4×8 compressed wood top – not sure exactly what it was – but in any event, while two could lift it, four was advised. I got it from an engineering firm that had gone out of business. I had it geared pretty well too. That was a good bench.

That’s another thing. Small parts / hardware storage. Cans vs. the store-bought mini-bin drawer sets. Pros and cons to each. I may end up with both.

Yeah. I’m happy. :-)

The table has to pull double duty. Most personal projects are woodworking. Engineering projects that need it are metalworking. Ergo the 5/8″ steel plate top. Two cannot lift it. The top plate alone is over 800 pounds.

You definitely have a point. Home Depot started selling cheap magnetic tool storage bars a couple years ago. I made the move to those from pegboard hooks for my wrenches, and it took some figuring out to mount them to the pegboard. I ended up slipping 1/2″ ply behind the pegboard in the area where my wrenches are.

If I had it to do again, I’d probably do what you recommend, but then have some pegboard on standoffs over part of the plywood. I still think it’s hard to beat pegboard for convenience when you have to reorganize a little.

Jim

Late to this party due to a bit of a roe with comcast on them turning off my equipment (modem) they consider EOL (End of Life). But here is my set up:

Main garage for daily parking but also maintenance and major repairs, the high ceil allow me to install that lift about 5 years ago as the aging process has limited my ability to work under a car on jack stands on a cold cruel floor. The mid life toy there is waiting for a rollover control module which did not like the removal of power from the replacing of 6 year old battery (it was called out in a service bulletin so they know they are jerks) and they fricking buried it in the wall behind the backseat. Two hours to remove the rear interior….Bloody Bavarians.

High shelves for longish term storage and used kitchen cabinets for service parts storage. Rolling tool boxes or carts for easy access to tools while cracking knuckles.

Lower garage, underneath the mother part of our mother/daughter arrangement was initially for parking cars. But as you can see is doing double duty the integration area for finishing my airplane and I have poly walls I put up for dust and extra light when it is time to paint said aircraft (or cars for that matter). Adjacent to this lower garage is my large workshop for (30’x30’x~10′) is for large projects. This is where the majority of my avatar was built. Note several work benches, pegboards for scanning and finding the parts that are called out in the assembly instructions. Second reverse view of the same area shows the shelving for the large parts for current project and an assortment of parts from other flying toys. Also note that even the ceilings are used for storage. Whether the stuff is leftover lumber from earlier projects or wings from the current projects.

Adjacent to this lower garage is my large workshop for (30’x30’x~10′) is for large projects. This is where the majority of my avatar was built. Note several work benches, pegboards for scanning and finding the parts that are called out in the assembly instructions. Second reverse view of the same area shows the shelving for the large parts for current project and an assortment of parts from other flying toys. Also note that even the ceilings are used for storage. Whether the stuff is leftover lumber from earlier projects or wings from the current projects.

The final work area is my woodworking shop which is were I did a lot of the finishing work and some furniture for the house, then later for untold numbers of pine wood derby cars, and late more advanced Eagle Scout projects. This shop have become overwhelmed from the pile up of hunnydoos placed down there by wife and children from my three month absence down in Florida for the airplane construction. That is my excuse and I am sticking by it….

This last little area is next to the wood shop and it the storage for everything with home ownership and tools & hardware. So I hope you find a bit of inspiration from the workshop messes I shared.

So I hope you find a bit of inspiration from the workshop messes I shared.

GLDIII, that is quite a setup. Lots of room, space to work, lots of options. Idle hands dare not enter there! Thanks for sharing the pictures.

Well, I am not doing a garage, but am ripping out w/w carpeting from ~900 sq ft basement, and replacing with laminate flooring, repainting, new baseboards, doing floor so it makes sort of 3 spaces, office, game area, and man cave/party space. So that keeps me out of trouble for quite a while.

My 3rd garage is seriously limited in the power department. I have 1 hanging bulb that doesn’t work. Furthermore, the electrical box is full.

What do you all think about a generator for power?

It would be noisy and expensive, but there’s no reason it couldn’t work. If you go that route, be sure the grounding is done well. I’d recommend professional testing.

What is your current garage service and how much current are you using? If the issue is just a full panel, that’s usually an easy upgrade.

Well, to put it outside the workspace where it belongs sounds a lot more expensive than just upgrading your electrical panel. What am I missing?

I suppose it really depends on how you intend to use the space, and how often. If you are looking for a persistent capability, with significant power draw, I’d lean toward running new circuits. If you are just looking to run new lights, I’d just extend an existing one.

Sure, a generator (depending on the rating and draw requirements) would work, but there is a lot of downside as far as regular usage.

When I rebuilt the house, I did include the ability to run the house (or part of it) on my generator, with the plug adapter on the exterior of the house and a cross-over switch at the panels. But that’s an emergency scenario.

In the end, I’d lean toward paying the man to run new circuits. But that’s just me.

Ok, it was an idea. I thought putting in a new bigger box sounded expensive.