Ricochet is the best place on the internet to discuss the issues of the day, either through commenting on posts or writing your own for our active and dynamic community in a fully moderated environment. In addition, the Ricochet Audio Network offers over 50 original podcasts with new episodes released every day.

Ask The Expert: Spent Nuclear Fuel Handling and Storage

Ask The Expert: Spent Nuclear Fuel Handling and Storage

A basilisk is a mythical creature able to kill with a single glance. Used or “spent” nuclear fuel would have a similar effect, if you were to stand close to it without benefit of shielding: Within a matter of minutes, you would receive a lethal radiation dose. Unlike basilisks, however, spent fuel isn’t out to get you, and is handled and stored safely at every nuclear power station in the United States. In contrast, new fuel that has never been loaded into a nuclear reactor has a very low — almost negligible level of radiation — and can be touched and directly handled without incurring any significant radiation dose.

A basilisk is a mythical creature able to kill with a single glance. Used or “spent” nuclear fuel would have a similar effect, if you were to stand close to it without benefit of shielding: Within a matter of minutes, you would receive a lethal radiation dose. Unlike basilisks, however, spent fuel isn’t out to get you, and is handled and stored safely at every nuclear power station in the United States. In contrast, new fuel that has never been loaded into a nuclear reactor has a very low — almost negligible level of radiation — and can be touched and directly handled without incurring any significant radiation dose.

The smallest unit of nuclear reactor fuel is a fuel pellet, a cylinder of compressed uranium dioxide, enriched to about 3 – 4.5% of the U-235 isotope. Each fuel pellet is less than half an inch in diameter and less than an inch long. Fuel pellets are loaded into a slender tube (called cladding) about 12 feet long, usually made of Zircaloy (a metallic alloy); the sealed tube is called a fuel rod, which looks similar to a wooden dowel. Fuel rods are arranged in an array called a fuel assembly. A boiling water reactor (BWR) has a 7 x 7 or 8 x 8 array of fuel rods running parallel to each other, in an assembly about five and a half inches square, about 14 to 15 feet long, weighing about 600 pounds; a typical boiling water reactor core holds between 500 and 600 such assemblies.

In contrast, a pressurized water reactor (PWR) has larger fuel assemblies that contain significantly more fuel rods — between 14 and 17 per side, though hexagonal arrays also exist — and weigh 1300 lbs or more. A typical pressurized water reactor core holds fewer than 200 fuel assemblies. A few spaces in each assembly are fitted with guide tubes instead of fuel rods, to allow control rods or in-core instrumentation to be inserted.

A reactor is typically refueled every 18 months, during which time about a third of the fuel assemblies are replaced. The assemblies selected for removal are the oldest and most depleted fuel; while they are not completely “used up,” they will no longer support reactor operation at 100% power and cannot maintain a chain reaction. Spent assemblies still contain fissionable materials – both uranium and a number of lighter fission products, most of which are radioactive — and their contents still spontaneously decay and emit neutrons. Consequently, the spent fuel assemblies continue to emit heat and radiation, which gradually decrease over a period of years.

Irradiated fuel must be shielded to prevent the escape of radiation. When the fuel is not enclosed inside the reactor, water is used as a shield. Gamma rays — the most penetrating form of radiation — will be attenuated by half when passing through a mere 18 inches of water. A 20-foot layer of water will cut the gamma radiation in half about 13 times or more, which is generally good enough to handle the fuel safely.

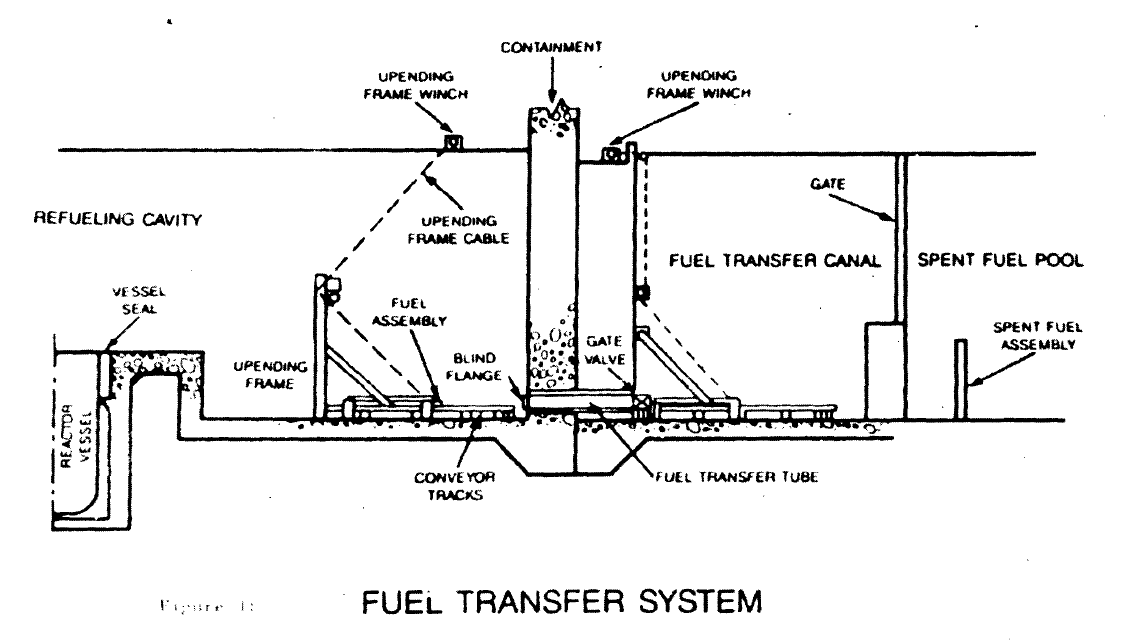

The reactor vessel is the deep pit on the left and is, itself, within a larger pit called the refueling cavity.

The reactor is located at the bottom of a refueling cavity, a concrete “pit” at least 22 feet deep. The reactor head is unbolted and — as it is lifted — the cavity is slowly flooded with water so that the head is never more than a few inches above the water surface. When the water reaches a depth of at least 20 feet, the head is stored and an underwater tunnel between the cavity and the spent fuel pool is opened. One-by-one, fuel assemblies are lifted out of the core with a crane, underwater at all times, and laid down on a transfer cart which transports the assembly out of the containment and into the spent fuel pool in an adjacent building. There, a crane upends the fuel assembly, lifts it, and inserts it into a fuel rack in the spent fuel pool. The process is repeated until the required amount of spent fuel has been removed and stored, one assembly at a time. During the entire process, the fuel assembly is kept as far under water as possible to protect fuel handling personnel from radiation.

Storage of spent fuel must meet the following objectives:

- Protect the fuel handling personnel and the public from radiation, and prevent the release of radioactive materials;

- Dissipate the decay heat produced by the fuel and keep the fuel from overheating and damaging its cladding;

- Prevent the fuel from returning to criticality, i.e., restarting the nuclear chain reaction (return to criticality is possible if fuel assemblies are packed too close to one another without any moderating or neutron-absorbing materials); and

- Protect the fuel from mechanical damage.

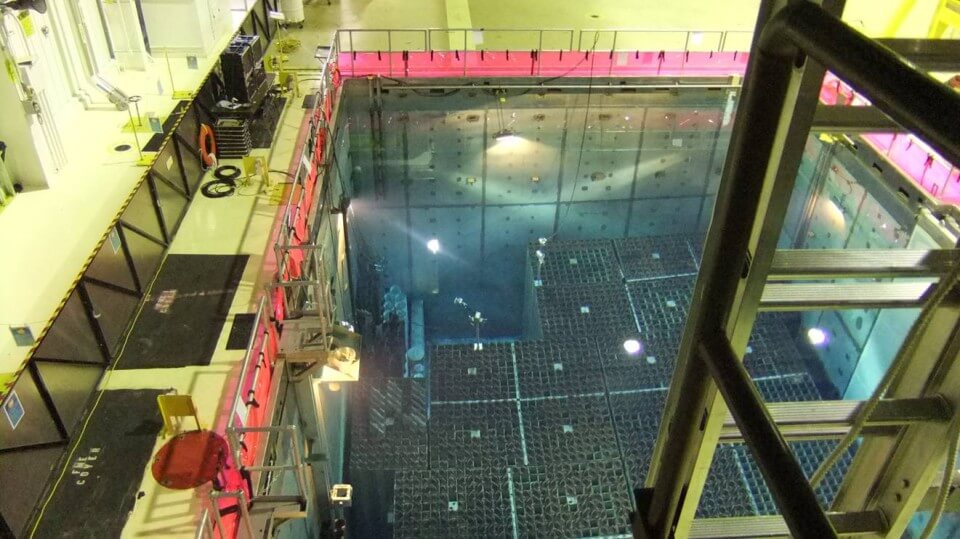

The spent fuel pool is deep enough to ensure that the top of the fuel racks are covered by at least 20 feet of water to provide adequate shielding. Heat is removed by a cooling system which circulates the pool water through a heat exchanger to remove decay heat. If this system were to fail, the pool would heat up gradually over a number of hours or days, and the heatup would be detected on instruments reading in the main control room. Cold water could be added using hoses to replace water lost by evaporation or boiling.

A spent fuel pool.

The fuel racks maintain proper separation between fuel assemblies and shield them from one another. The original fuel racks at most stations use physical space to separate fuel assemblies and control reactivity. As these fuel racks filled up over the years, they were replaced with new racks which packed fuel assemblies much closer together (saving space) but added divider plates between assemblies incorporating neutron absorbing materials containing boron, such as boron carbide. Boron-10 (about 20% of naturally occurring boron) is a powerful absorber of neutrons, and therefore it is useful in controlling the reactivity of the fuel. In a PWR fuel pool, boric acid will be added to the pool water to a concentration of up to 2000 ppm boron to further control reactivity and prevent a return to criticality (this is not an option in a BWR pool, which utilizes clean, demineralized water). The fuel racks keep the fuel oriented upright and protect it from mechanical damage. Administrative controls are used to prevent foreign objects from being dropped into the pool.

Fuel assemblies remain in the spent fuel pool until their decay heat production has reduced sufficiently that they may be moved to dry storage without danger of overheating. The NRC requires pool storage for a minimum of one year, but it generally takes five years or more for decay heat production to decline sufficiently. Customarily, utilities have been leaving fuel in the pool until the amount of space remaining in the pool becomes an issue. Most nuclear power stations have sufficient space in their spent fuel storage pool racks for approximately 20 to 25 years of spent fuel. When it becomes necessary to free up space in the spent fuel pool, the oldest fuel assemblies are removed and transferred to dry storage casks located a distance away from the plant, in an Independent Spent Fuel Storage Installation (ISFSI) to begin the second phase of their storage.

Storage casks

The dry storage cask system consists of two parts: a hermetically sealed metal canister to permanently contain the fuel, inside one of several types of overpack designed for transport, long-term storage, or both. The metal canister contains a storage rack inside, similar to the rack in the spent fuel pool. They typically hold between about 70 assemblies from a boiling water reactor, or between 24 to 32 from a pressurized water reactor, and weighs approximately 100,000 lb. However, the walls are too thin to provide adequate radiation and heat shielding, which is why the canister is kept inside an overpack at all times. The overpack is made of metal and concrete and is designed to provide enough shielding to allow personnel to work around the cask. The overpack for long-term storage weighs well over 100,000 lb empty. With a loaded canister inside, the whole storage cask weighs between 220,000 and 280,000 lb.

The canister is placed into a transport cask, lowered into the spent fuel pool, and loaded with fuel assemblies underwater. A lid is placed on the transport cask, which provides radiation shielding when the cask is removed from the water. The transport cask is removed to an area where it can be drained and decontaminated. The canister lid is welded on, all water and air is removed from the canister, and the interior is inerted with helium. The canister is transported to an outdoor cask storage area, and transferred from the transport cask to a storage cask. This is done by placing the transport cask on top of the storage cask, and lowering the canister from the transport cask to the storage cask while keeping the canister shielded at all times. The storage cask is then moved to its permanent location on a concrete slab. Though outdoors, the cask is protected from earthquakes by being bolted to the slab. The cask itself protects the fuel canister inside from wind-driven missiles and storms of all kinds.

Decay heat from the fuel assemblies is transferred to the wall of the canister (inside the cask) by natural convection of the helium inside the canister. The amount of decay heat produced by the fuel in one cask at the time of loading may vary typically from one to fifteen kilowatts or more, depending on how long the fuel assemblies have been out of the reactor core. The helium inside the canister can reach a temperature of several hundred degrees in temperature, and helps transfer the heat to the outer wall of the canister. The outer storage cask is a thick-walled concrete overpack which provides shielding from both radiation and heat, and is equipped with air vents near the top and bottom to allow the canister to cool inside the overpack by natural convection. The air vents have a labyrinth design to prevent radiation from escaping (radiation can travel only in a straight line).

Detailed records are kept on fuel handling. Each fuel assembly has a paper trail documenting where and when it was located in the reactor core for all three cycles; where it was located in the spent fuel rack and the dates of storage and removal; and which cask it was loaded into and the date of loading, among other information. A typical reactor refueling cycle produces enough spent fuel to require two or three casks. Approximately 200 such casks loaded annually nationwide.

The 11-minute video below shows the process of transferring fuel from the pool to casks at Diablo Canyon, a 2-unit PWR in California. The video also shows how at each stage of the process, seismic restraints are installed to protect the cask from possible earthquakes. This is required at all nuclear stations in the United States, not just in California.

https://www.youtube.com/watch?v=mILvWNgggfU

The third phase of storage would consist of long-term storage in a central repository, should one ever be constructed. In order to transport the fuel to such a repository, it would be necessary to transfer the canisters inside the storage casks to an overpack designed for rail transport, as the casks are too heavy to be transported by rail. These transport casks would likely have to be oriented horizontally in order to pass through underpasses along the route.

The Nuclear Waste Policy Act of 1982 required the Department of Energy to site, construct, and operate an underground waste repository in a geologically stable location. In 1987, DoE established Yucca Mountain as the the designated location. While more than $30 billion in taxes has been collected from nuclear utilities since 1982 — and approximately $9 billion has been spent on studies — no repository has been built. Utilities have sued the federal government to recover their costs of nuclear fuel storage. Collection of the fees was halted by a court order, and these payments stopped in 2014. The DoE attempted to withdraw its license application for Yucca Mountain in 2010, but this action was been opposed by lawsuits. Pursuant to a 2013 court order, the NRC resumed technical and environmental reviews and published the final volumes of its safety evaluation report in January 2015. Work continues on an environmental impact statement, and it is still unknown when a license may be issued. It is likely that outdoor dry cask storage will be the predominant method of spent fuel storage in the United States for decades to come.

Published in General

It’s my understanding that Harry Reid is the #1 reason Yucca Mountain never came to fruition.

Terrific article, thanks.

Epic post!

You would think by the way the Left talks, the disposal process has men with shovels scooping atomic sludge into leaking 55 gallon drums that are then rolled into pristine rivers or stored in orphanages.

Radiation safety boils down to shielding + distance + time.

Tom Meyer: Is there a reason why the head is drawn above the surface? Why not keep it underwater as well?

[I’m at work now, and can’t quote for some reason]

That’s a good question, and I am not 100% sure but I suspect that there are electrical things attached to the head that they don’t want to get wet. All the control rod drives are up there (for a PWR; for a BWR, the CRDs are on the bottom, so I don’t know if they do it the same way).

Old Buckeye: It’s my understanding that Harry Reid is the #1 reason Yucca Mountain never came to fruition.

One of the big reasons, for sure. He was opposed to it, and prevented it from moving forward while he was Majority Leader (2006-2014); I am not sure how much influence he had before then (probably a lot). The repository was supposed to be built and in use by 1998, and that didn’t even come close to happening. It has been studied to death, probably in response to persistent opposition that will never be satisfied of its safety and stability.

Yes there is a reason. In the case of PWRs, the cooling water contains boric acid which is used as a moderator for fission products. While the stainless steel cladding on the internal portions of the head work just fine for exposure to boric acid, the heads themselves are low alloy or carbon steel, which corrodes when exposed to boric acid for any significant duration, especially when that boric acid is combined with oxygen in air. This of course does not mention the electrical equipment on the control rod drives (CRDs) attached to a PWRs head. While the CRDs can tolerate some spray and humidity, they are not designed to be submerged.

BWR heads are generally carbon steel as well. Although BWRs do not use boric acid as a fission product moderator, exposure to coolant chemistry in a submerged atmosphere may cause other corrosion issues or issues with any coatings used on it. Should those coatings flake off in the coolant water, that is foreign material that you’ll have to control and remove before operating your reactor or the foreign material may cause damage to the nuclear fuel.

Thick concrete containment structures have additional benefits other than just penetration by planes or other missiles. Concrete retains water, which is exceptionally useful for radiation shielding and that is necessary for protection of the public during accident scenarios. Beyond that, the concrete can be used in different designs to provide different methods of post-accident containment. Some containment structures are essentially big pressure tight steel cans, with concrete feet away from the steel can for radiation barrier. In this case the concrete does not help the can resist internal pressure. Other containment structures are more like a beer can in a fully encompassing concrete koozie. The steel provides the leak tight barrier, while the concrete immediately assists in the pressure retention, while also providing a radiation barrier.

Some old BWRs like Big Rock Point did without an exterior concrete containment altogether and operated into the 1990s in that fashion.

BSB can you name a plant that actually uses a polar crane as the main manipulator of fuel during refueling? Most PWRs and BWRs that I can think of use specialty fuel handling cranes and devices made by Stearns Rogers or PAR.

Here is an example at Columbia (BWR): https://www.youtube.com/watch?v=A-tQoxL8e7s

Here is an example at Commanche Peak (PWR): https://www.youtube.com/watch?v=IoCfapqYy00

Yeah, I’d forgotten about the corrosion problem. At Davis-Besse some years ago they had a boric acid leak that ate all the way through over 5 inches of carbon steel on the head, leaving only 3/8″ of stainless steel internal cladding to resist 2235 psig reactor pressure.

I know about that one quite well.

So the head is always above-water. Got it. Thanks!

Ricochet: ya learn stuff.

I deleted the word “polar.” More detail than needed, especially if it’s not accurate.

Cool beans, daddy-o.

Yeah, now that I think about it, moving fuel with the polar crane would be unnecessarily hard. You’d be rotating it a lot, and it’s really big and slow.

Metalheaddoc

Epic post!

You would think by the way the Left talks, the disposal process has men with shovels scooping atomic sludge into leaking 55 gallon drums that are then rolled into pristine rivers or stored in orphanages.

Radiation safety boils down to shielding + distance + time.

Thanks.

Of course we don’t roll the leaky 55 gallon drums into pristine rivers or store them in orphanages. We sell them to farmers for fertilizer. Where did you think genetically modified foods come from?

Well, beyond the hassle of using a crane that may be 50 to 100+ feet above the reactor vessel lip, the cranes typically have much higher capacities than necessary for lifting a 700-1500 lb fuel assembly. As a result, it makes little sense to use a 100 ton to 250 ton crane for something a specialty piece of equipment is much better suited to. Polar cranes are often used for many other major equipment lifts that go on during refueling outages. Since they are so heavily used during outages, specific lifts are typically tightly scheduled and controlled since delays may impact the overall outage time. Some plants have gone back and added more small cranes within the containment buildings to give relief to the scheduled polar crane duty, so they can make smaller lifts without having to use that massive polar crane and tie up its time.

*For those that don’t understand the conversation BSB and I are having here, many nuclear power plant containment buildings have large gantry or bridge cranes that sit above most of the equipment within the containment building. These cranes move back and forth on rails mounted in the upper portion of the building. However, many of these buildings are round and thus there is a need for a crane that runs on circular tracks to maximize the maneuvering capacities of installed cranes. Polar cranes, as we discuss them, simply move around a circular track for the purposes of lifting large items.

http://www.konecranes.com/industries/nuclear-equipment-services/polar-cranes

http://www.nucranemfg.com/images/PCLiftingRV.jpg

Thanks to all for the kind words.

Query for the better-informed:

Could someone provide/link to an explanation for why uranium dioxide pellets are relatively safe to handle and emit very little radiation individually, but are capable of generating great heat in a reactor?

Is it something to do with getting a critical mass of the stuff together? I’ve spent a few minutes googling and have come up surprisingly empty.

Something like that. Critical mass just means that there is enough Uranium for the reaction to be self-sustaining. You can have a self-sustaining reaction that doesn’t produce a notable amount of heat (early reactors were piles of the stuff in a lab). A single pellet isn’t a critical mass. I think a rod might be, but I don’t recall. Certainly by the time they are assembled into their assemblies, they reach critical mass. More than that, the sheer number of pellets produces enough energy to boil the water.

This is different, though, from what boils the water in the cooling tanks. That’s the result of the byproducts of fission. Cesium and Strontium (I don’t remember the isotope numbers) have really short half-lives, and so they put off enough energy to kill you in short order, first by roasting you, then microwaving you, and finally with radiation poisoning.

It’s like adding heating elements to a stove. One heating element on extremely low won’t burn your hand. A thousand of them, though, will.

Thank you both.

New fuel is not radioactive because it has not been irradiated with neutrons which get the chain reaction started; it doesn’t matter how much of it there is. You can handle entire new fuel assemblies without danger. Spent fuel is radioactive because it is full of radioactive fission products, such as strontium-90 and cesium-137, that emit neutrons as well as gamma and beta radiation (lots more detail above in anonymous’s comment). Some of the neutrons can split additional uranium-235 atoms, keeping the process going (although at a low level).

Interestingly, a brand-new reactor, full of brand-new fuel, obviously has much more than a critical mass, but there are not enough neutrons to get the party started. Neutron source pins are inserted to irradiate the fuel and get the chain reaction started, and then they are removed. They are never needed again, as only a portion of the fuel is replaced at each refueling, and the previously irradiated fuel generates enough neutrons to get the new fuel going.

What the heck are Neutron source pins made out of?

I don’t actually know what was used in US power reactors, but there are a number of substances that emit neutrons, such as Californium-252, that could work.